There are materials on the market that can be used for constructing various types of facilities. Examples include PIR and PUR sandwich panels designed for cold stores and freezers. These panels are characterized by high gas tightness, resistance to mechanical damage, as well as moisture and fire resistance. What distinguishes these two types of panels from each other? Where can they be purchased? Read on!

BLOG

-

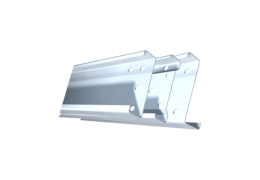

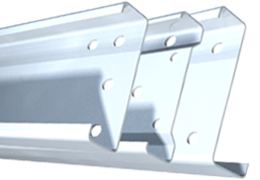

Which steel profiles to choose for a shelter?Read more...

Which steel profiles to choose for a shelter?Read more...Simple, practical, and enhancing the aesthetics of the exterior façade. It’s no surprise that shelters are so popular. However, before construction, they need to be properly designed, and steel profiles are commonly used for this purpose. Which ones should you choose?

-

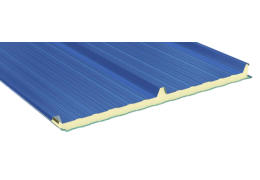

Which sandwich panel should be used for a garage roof?Read more...

Which sandwich panel should be used for a garage roof?Read more...This question has often been asked by people looking for information on the most popular methods for finishing garage roofs. Depending on the needs, sandwich panels with a core made of polyurethane foam (PUR) or polyisocyanurate foam (PIR) are most commonly used. Both types have similar properties, but there are some differences between them. What are they? Read on!

-

Is Balcony Photovoltaics Worth It? Everything You Need to Know About PV Panels in Apartment BuildingsRead more...

Is Balcony Photovoltaics Worth It? Everything You Need to Know About PV Panels in Apartment BuildingsRead more...In Poland, we have been generating electricity from solar energy since 2011. Despite the passing years, most people still associate these installations primarily with photovoltaic farms, industrial facilities, and single-family houses. Balcony photovoltaics in apartment buildings is a relatively new trend that is just starting to gain popularity in Poland. Which PV panels should you choose, and where is the best place to install them? What requirements must be met to install solar panels on a...

-

Installation of photovoltaic panels on roof panels.Read more...

Installation of photovoltaic panels on roof panels.Read more...In order for the building to withstand solar cell load, it is best if this type of investment is planned at the design stage of the facility. However, it is also possible to install photovoltaic panels at a later time, provided that the appropriate conditions are met and that the roofing is not affected. In our article, we discuss the topic of installing modern systems using solar energy. We also provide possible directions for the development of the photovoltaic industry.

-

Steel profilesRead more...

Steel profilesRead more...Nowadays, there is no doubt that one of the most commonly used materials in industry are steel profiles. This happens for a reason - they are distinguished by their extraordinary durability, and at the same time they allow the creation of complex structures, such as halls, storage racks and many others. Before you start using these types of elements for your purposes, you should know the most important steel properties, their advantages, as well as the most common use. Thanks to this, you'll...

-

What are the advantages of sandwich panel construction?Read more...

What are the advantages of sandwich panel construction?Read more...Regardless of whether it is a production hall, warehouse or public utility facility, during each investment, emphasis is placed on two basic factors: cost and construction time. The use of a modern solution, such as sandwich panels, will be a source of benefits in both these matters. Not only will it significantly accelerate the entire process, but also optimize the expenses incurred during it.

-

What to consider when choosing a sandwich panel?Read more...

What to consider when choosing a sandwich panel?Read more...The purpose of the newly created object is one of the features that are crucial when selecting building materials. The future use of real estate affects many other issues, such as minimum strength or necessary thermal insulation of sandwich panels used to erect a structure. So how do you choose the right components? Which of them will make the building serve its users for many years, ensuring security and functionality?

-

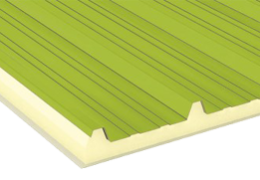

Sandwich panels, construction and applications.Read more...

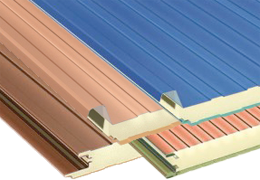

Sandwich panels, construction and applications.Read more...Lightweight sandwich panels are a commonly used material for building walls or roofs of halls, public or industrial facilities. They are made of construction materials and insulation and construction materials. They include outer layers, in the form of cladding, as well as a middle layer, which aims to provide the greatest possible thermal insulation. The individual panels are joined together and then bolted to the support frames, thus creating a roof or wall surface.

-

What is a wall sandwich panel?Read more...

What is a wall sandwich panel?Read more...An excellent solution for finishing industrial, utility and farm buildings, where it is necessary to create the right conditions, are wall sandwich panels.

-

What is a roof sandwich panel?Read more...

What is a roof sandwich panel?Read more...The presented solution is used, among others for roofing of commercial and industrial buildings. It is also used to renovate roofing made of asbestos. Roof panels made of insulation and construction materials are an extremely functional solution, appreciated, among others for its strength and good thermal insulation properties.

Latest comments